The correct rear brake pedal for a high exhaust came in just a few days ago, and I think that was pretty much the last part I needed, while I am putting it together I'm not sure what to do with the exhaust.

I have an original high muffler, but it has some scrapes and rusty bits and the protectors are pretty bad, so another option that I would think goes really well with the seat, would be a racing muffler. original ones are made from "unobtainium", so I will probably have to make it myself. Made a mockup with paper to get the idea and put on the original racing protector that I have, just like the one on the C110 racer I'm building.

I have an original high muffler, but it has some scrapes and rusty bits and the protectors are pretty bad, so another option that I would think goes really well with the seat, would be a racing muffler. original ones are made from "unobtainium", so I will probably have to make it myself. Made a mockup with paper to get the idea and put on the original racing protector that I have, just like the one on the C110 racer I'm building.And then how to build it, with the mountings to the original muffler mount just before the shock, as it is pictured in the manual. or to the upper shock mount, as all megaphones are, that I've seen, but even though that is probably more original I think that doesn't look all that nice.

While building I still find small things to improve and order new parts for, such as the oil lines. I wanted these to run up to the carburetor again, just like original, as I had run it with only one line from the case directly to the head, but in cold weather this resulted in a frozen carb.

So I ordered new oil lines, to bend them in the right shape and not one that had evolved over multiple owners fiddling with them.

Also fitted NOS grips and had quite a fight getting them on as they were a little tight and just a bit hardened over time.

Cables are in place, as I also ordered a new clutch cable so everything would match in color, made a new throttle cable and replaced the blue sheath on the dimmer switch with some grey so that would match too.

Just a few little thing to do before I can take the bike apart again, so I can take it down the stairs to rebuild it on the ground floor and get it running.

The zinc plating came back, so I could start putting parts back on the bike again to rebuild it.

Still waiting for some new parts like the steering races and then it can be fully put back together.

I just recieved an e-mail from my painter, where I dropped of 2 bikes last week, that my bike is ready. and next week he will start on my dad's CB100.

And some pictures included also, I can hardly wait to pick it up and start putting it together.

.JPG)

.JPG)

.JPG)

.JPG)

Although I didn't think it would be done so quickly, so the zincplating still has to be sent out.

Bridgestones

My new 2,25x17 bridgestone tires, just in from japan, thanks to masato

Mounted to my newly laced 17" wheels for my C110 streetbike, with 17x1.20 Morad shouldered alloy rims by Poelma.

They're not cheap, but I wanted a classic profile with good handling and in the original size. No inferior chinese rubber shaped like a tire.

Front forks mounted

This is pretty much al the ready to go parts I can bolt on now, next will be some swapping of rims, hubs and spokes, so both C110's can get their wheels built.

And sending out some cylinders to be bored out to 60cc's so I can rebuild the engines.

Cool stuff.......oil, that is

I had this idea for a while, just been looking for the right parts.

Don't know if I really like the look, but it was fun to build, something unique, I mean, how many C110 oilcoolers have you seen?

Kijima dress up kit for C110

Here you see my C110 Kijima dress up kit for the C110 engine I've been building.Clutch, points and valve covers with some extra cooling capacity.

those of you who know the Kijima catalog are now questioning what this is, they are actually left side head covers for the OHC engines, modified to fit C110. Valve covers also need to be modified, or they jam against the rocker cover of a pushrod motor.

The motor I've built for Ralph also had these covers, it was his idea and I "borrowed" it for my own motor.

Didn't do much with the motor lately, as my SS motors kept givving me problems, but that is prety much over now, so I had time to spend on this little 60cc pushrod powerplant. It's almost ready now, just waiting for some special bolts and I want to do something special with the oil-line...to be continued.

How to make your own lightweight valve spring retainers

As the title says, lightweight retainers.

Seen on this blog before because I made them for my oldschool SS50 engine and my earlier C110 engine.

Now I'm rebuilding the original C110 engine that belongs under my C110, also with 60cc so I can keep up with modern traffic, and some more racing tricks, like lightweight retainers.

step 1:

Mount the retainers to a piece of perforated sheetmetal and spraypaint the other side.

step 2:

You now have the pattern of what to grind away, start grinding. I've used a 1mm cutting disc on an anglegrinder mounted in the vice, holding the retainers in vicegrips.

weight before:

weight after:

disclaimer: my scales ar not that accurate, when measured seperately one piece weighs 4 gramms and lightened 3 gramms.

So let's say you can achieve a 25-30% reduction in weight.

No titanium, but it only costs you some time and a little effort, no money.

And this is what it looks like, mounted in a C110 head

Maybe I should get some seethrough valvecovers...

Wheelbuilding

From the cancelled CR110 replica project I had some 18" alloy rims left over, so I decided to use them on the C110.Found a set of original S90 spokes, old style spoke pattern, crossed over 6 (instead of the normal 2 or 4)

And this is what a wheel looks like when it's done.

Bridgestone AC01 racing tyre, will probably wear out pretty quickly with roaduse, but I do like skinny tires and there is no other option which looks and performes good.

The wheels look a bit flashy now, compare to the rest of the bike which is a little rusty and dirty, but soon it will be taken appart for painting.

C110 breaking

It has been a while since the last blog, but that doesn't mean I didn't do anything.The C110 has had its front brake stay replaced.

The balljoint system worked...until I really hit the brakes and the tab on the forks bent, causing the balljoint to end up between the spokes.

So I searched if I could find some bearings the size of the original silentblocks, but nothing really had the right dimensions. Luckaly my dad had some free time to spend behind the lathe and he created some teflon and stainless bushings.

This ads a lot of braking power, because non is consumed anymore for warping the silentblocks

C110 racing cam

How can you get more power out of a C110 engine? Fit it with a racing camshaft.Only one problem, racing cams are not really available anymore.

I've seen some adds of old american aftermarket suppliers that had cams for Honda's including the 50/55cc OHV engines, but have never run across these camshafts for sale anywhere.

Luckaly my dad has some experience in making his own camshafts.

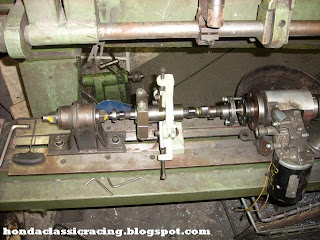

The C110 camshaft in line with a BMW R50S camshaft that will provide the profile.

Grinding stone, grinding away the C110 camshaft, this will result in a smaller ground cirkel, but also a higher lift and longer duration.

Finished product, the intake cam is reground, looks small next to the original exhaust cam, but because the groundcirkel is smaller, it is actually an inprovement.

Already made a testrun and you can feel the extra power in the higher revs without losing a lot lowdown.

C110 cam lift profile (not valve lift) compared to some others, the intake cam is now reground to the profile marked 50s,69s, clearly visible that it improves lift and duration.

C110 engine, but not my own

Been busy with a lot of things, but didn't take much pictures of my own projects,so here is some of the C110 engine I have been rebuilding for Ralph

Ported head:

Everything glassbead blasted and some fresh paint on the cast steel parts:

Clutch pressure pin / oil guide stolen from my extra motor as the one that was in Ralph's motor was broken. Anyone has a spare?

Kijima ohc headcover in the lathe:

Now it is a cluch cover:

Modified finned tappet covers:

Also a Kijima ohc headcover as a pointscover:

Modifying a webco Z50 intake manifold for the C110 head:

With homebuilt heat isolator.

Taken the flange off, because there was no fitting carb for it, now a rubber flange off an SS50 manifold so we can fit any slant flange carb:

Top view:

It's almost done now, just some special oil line and some gaskets for the manifold and we can start thinking of starting it up and seeing how it runs.

Look what I found

When wondering around the attic of the local Honda shop, I found a set of original C110 footpeg rubbers, no longer available from Honda directly.Found these in a bunch of NOS parts they have.

Ignition up and...not running yet

Yesterday I finished the ignition on the C110 "race" engine, I wanted something a bit lighter then the stock flywheel, but I didn't want to run a battery.So I modified a backplate off one of those cheap inner rotor pitbike ignitions to fit into the C110 case.

Used a 6v-12v tap converter meant for an OHC engine to fit the rotor, and a little tinkering to get everything lined up.

The engine went back in the frame and I mounted the CDI-unit and coil, easy access on the side and it just fits under my narrowed cover. Checked it to see that I had spark and then made an off switch in my throttle housing, from an old CB72 starter button.

Getting really close to starting her up for the first time, I'm interested to hear what the weight loss on the crankshaft will sound like.